Customer challenges

- Operator in SSA had outdated and infrequent production well test data due to the crane load and space constraints on small unmanned platforms

- Existing platform separators not suitable for brownfield production conditions

- Operator was relying on simulations and conventional downhole data-based sampling for production allocation, discrepancies with shared fiscal metering were evident

- Lack of representative Pressure Volume Temperature (PVT) data

- Production from diverse reservoirs, from undersaturated to mature and post-mature, with flow regime challenges such as foam, heavy oil, emulsions, and slugging

- Total gas production essential to design upcoming LNG plant

Expro Excellence

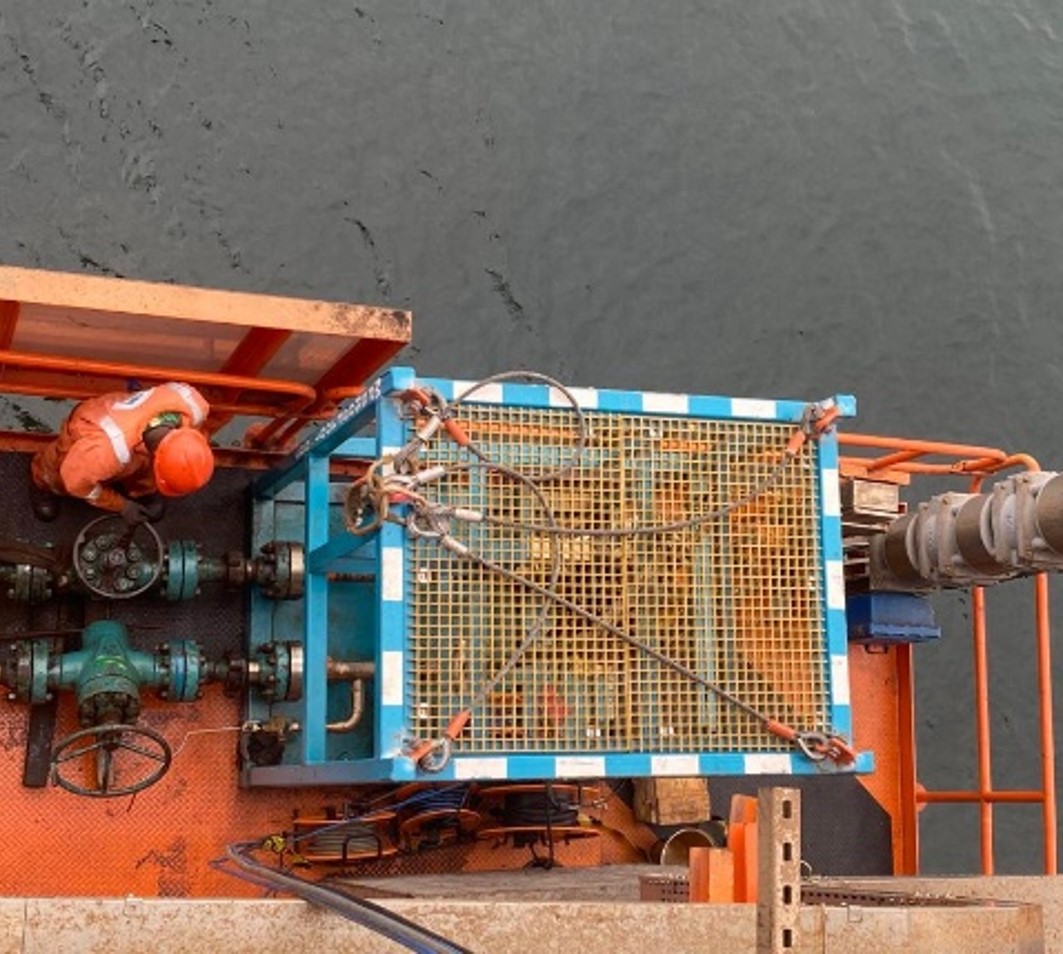

- Expro provided a compact MPFM testing skid along with Mini Separator for onsite PVT analysis

- Seamless flareless production testing of over 40 wells across 8 platforms with diverse Gas Oil Ratios (GOR) of 6 to 8250 Sm3/Sm3, API gravity of 14-52 and water cuts ranging from 0% to 96%

- Wide turndown multiphase measurement solution provided across the field with single MPFM and Mini Separator unit

- Testing performed around the clock with no HSE events

Value to client

- Accurate production allocation data across all tested platforms, validation of water cut sample points, and verification of simulation models

- Reduced testing equipment load (less than 3000 kilograms per lift) and footprint (less than 4-meter square) minimized personnel requirements and elimination of flaring and carbon emissions

- Customer leveraged well test data to perform well intervention and workovers such as acid wash, downhole gauge replacement

- Asphaltene issue identified on a well with no flow measurement