A North Sea Operator needed to mitigate 13 3/8” casing wear and torque during the drilling of a 12 1/4” section through chalk at a 60° inclination. Typically, in the southern North Sea high friction factors in the long chalk sections induce harmonic torque frequencies that travel up and down the drill string. In the past, the demand for full soft-torque operating has caused over-torqued connections due to the exceptional high variation in rotary speeds.

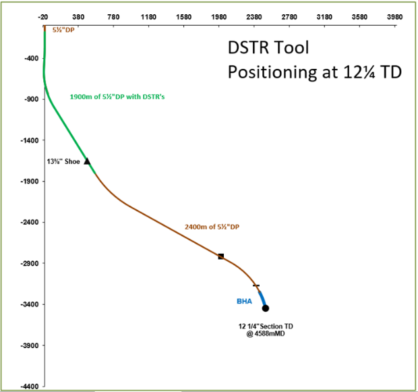

Expro recommended the placement of multiple 5 1/2” Drill String Torque Reducers (DSTR™) to help decrease casing and drill pipe wear, dampen stick-slip, and reduce torque.

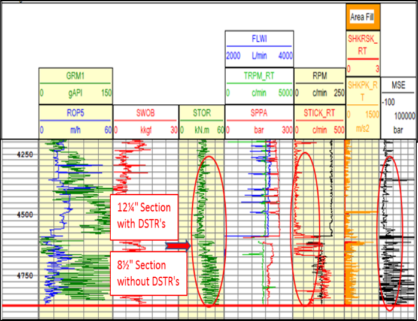

The use of the 5 1/2” DSTR™ tools provided the necessary torque reduction and stick-slip mitigation in the 12 1/4” section, keeping the torque values at the surface within the recommended torque limits. The 13 3/8” casing was protected and will be in good condition if a future re-entry is planned.

In the consequent 8 1/2” section where no DSTR™ tools were run, clear evidence of higher torque and stick-slip was present despite compatible mud properties, 5 1/2” drill pipe inside the casing (lower FF), a lighter 8 1/2” bottom hole assembly, and 300m of lighter 5” drill pipe.