Customer challenges

- During maintenance activities on a geothermal installation (two wells, drilled circa. 2013/2014) in The Netherlands, the wells were shut-in and downtime was optimised by undertaking well integrity checks, comparing data from surveys two years ago

- The objectives were: to determine the well integrity status of the producer and injector wells; perform casing integrity measurements (both casing ID and wall thickness)

Expro Excellence

- Expro delivered a comprehensive investigation programme through its fleet of wireline trucks: 60-arm multi-finger caliper (MFC) and magnetic imaging defectoscope (MID) tool, further complemented by reporting by specialists within the Data Analysis Centre

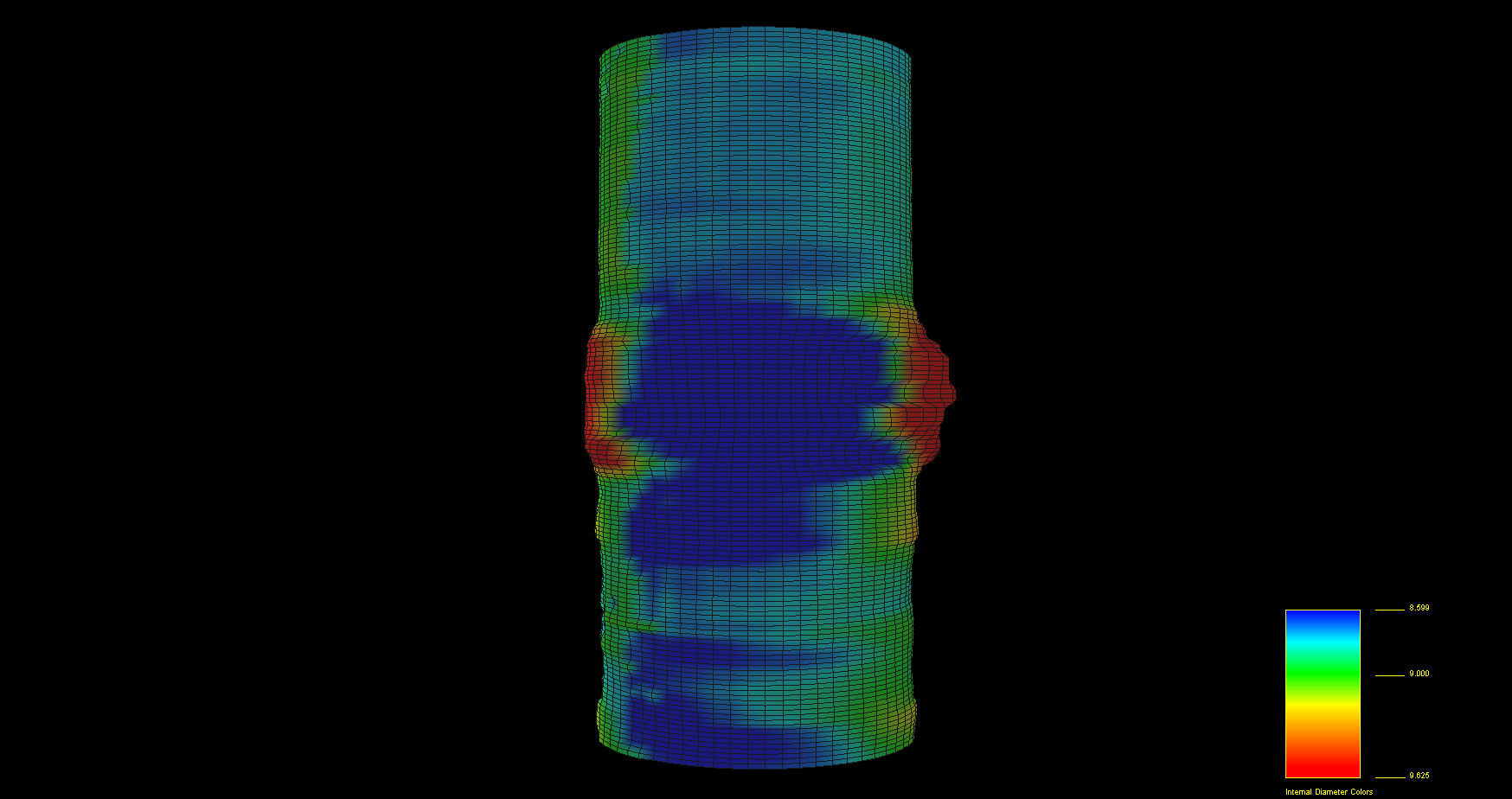

- Interpretation of the data established that a section of the 9 5/8" casing in the producer well had collapsed - sections of the casing were now deformed into an oval shape, caused by formation movement (deformation recorded by the caliper tool with a change in gamma ray response that indicated a change in lithology)

- Recommended slickine operations were required prior to commencing operations

Value to client

- A major repair programme (following complete failure) was avoided with proactive remediation by means of installation of a scab liner (extending the 6 5/8" casing into the 9 5/8") - this has now been established by the client as a new baseline for the scab liner

- Reduced costs and environmental impact as natural gas would have been required to heat up the greenhouses for any period of time the wells were out of production

- Government subsidies are suspended for every day that the wells are out of production