Case Study

ActiveSONAR contributes to “zero flaring” gas compression

Contact

In Brief

Non-intrusive measurements ensured proper design sizing for the compressors and helped achieve "zero flaring" gas compression

Region

Customer Challenges

- A customer in the Middle East required four gas compression packages

- Flow rate measurements and diagnostics are essential for multiple separator gas outlets in the customer's process facility for compressor design sizing and fulfilling their 'zero flaring' gas compression project

Expro Excellence

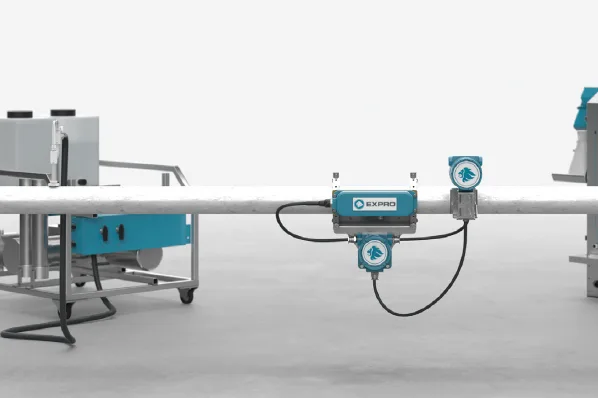

- Expro proposed a non-intrusive clamp-on ActiveSONAR meter

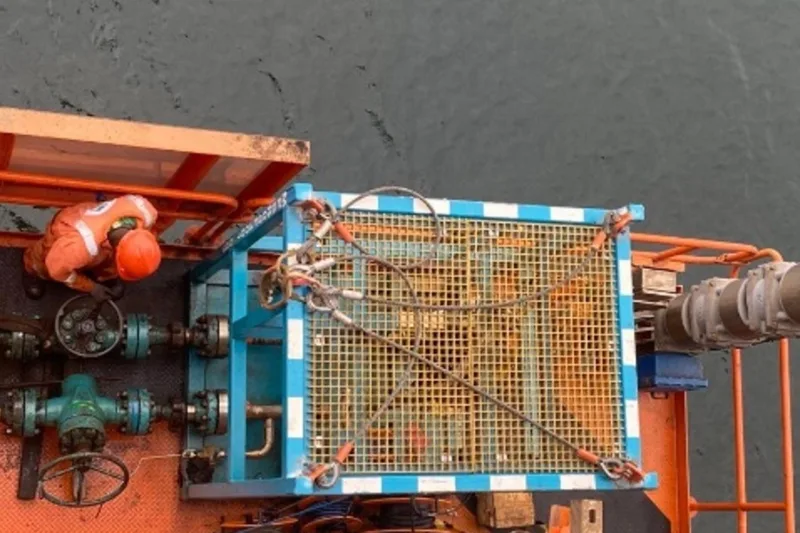

- Different sizes 4in, 6in and 8in were installed on high pressure and low-pressure separators across the customer's process facility

- Real-time flow rate data was provided covering a wide range from 1500 -27000 Sm3/d

- SONAR met diagnostics indicated unstable flow that correlated with upstream operations

- SONAR meters were also able to qualitatively identify liquid carryover and the presence of wetness in certain separator gas outlets

Value to Client

- The customer received an integrated solution with SONAR meters and multiple Expro product lines

- Expro provided insight into liquid carryover in the gas tree which could have potentially led to inefficient compression and equipment damage

- Expro provided the customer with additional separator stream to unload the liquid and optimise facility throughput before installation of compressors

- Non-intrusive measurements ensured proper design sizing for the compressors and helped achieve "zero flaring" gas compression

- The customer could certify that their process plants were running at maximum efficiency

Contact

For further information, please contact WFM@expro.com.

©2025 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU