Case Study

Expro provides downhole fluid sampling and onsite analysis for CCS stratigraphic wells

Contact

In Brief

Using Expro’s PCS BHS tool and onsite analysis services, samples were validated on site location and early characterization of the reservoir fluids was determined

Region

Customer Challenges

- Expro collaborated with the customer's Carbon Capture and Storage (CCS) team to conduct Bottom Hole Sampling (BHS) and perform reservoir fluids onsite analysis

- Representative Bottom Hole Sampling (BHS) plays a critical role in CCS projects by providing accurate data for reservoir fluid analysis which is essential for understanding the reservoir’s capacity and behavior. BHS also supports compliance with environmental regulations (Environmental Protection Agency - EPA) by providing the necessary data to demonstrate that the CO2 is being stored safely and effectively. BHS helps in managing risks by detecting potential issues early, such as impurities or unexpected chemical reactions, allowing for timely intervention and risk mitigation

- Our customer was particularly interested in the Pressure Compensated Sampler (PCS) tool to collect representative reservoir fluids and Expro’s capabilities to develop an onsite sample validation protocol for reservoir water samples. Oxy was looking to capture sufficient volumes of representative reservoir water samples for NORM, water chemistry analysis and aquifer geochemistry studies

Expro Excellence

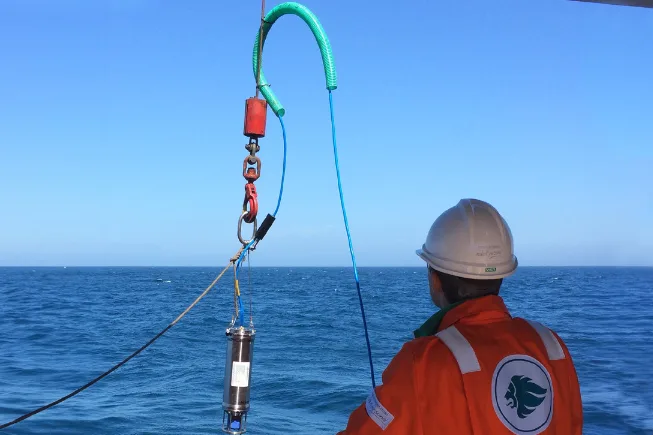

- Expro mobilized a compact and mobile laboratory to the site location and deployed the PCS BHS on wireline which can function in zones with low reservoir pressures and prone to sand production issues, in multiple zones per well

- In collaboration with the customer, Expro established a protocol to validate the quality of the samples collected during BHS operations at the well site

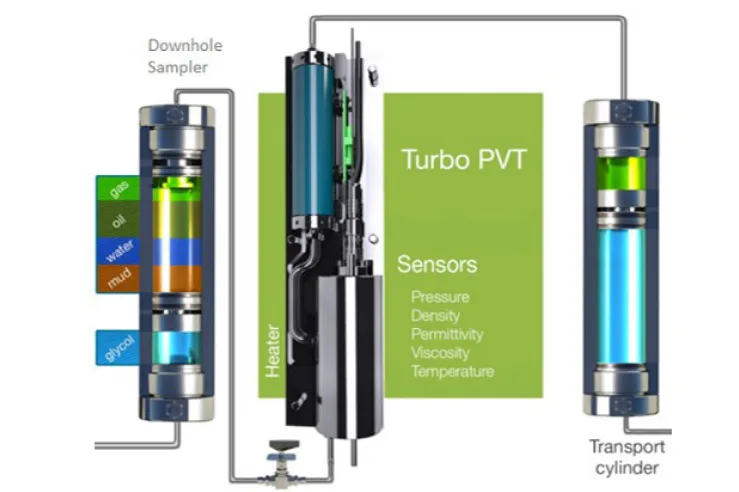

- Pressurized samples were flashed on location to perform onsite water analysis (density, pH, resistivity, conductivity, salinity, and TDS)

- Reservoir fluid samples were collected, maintained at reservoir conditions, and validated at the well site in a single operation

Value to Client

- Using Expro’s PCS BHS tool and onsite analysis services, samples were validated on site location and early characterization of the reservoir fluids was determined

- With all operations performed and all data measured by Expro at the well site, the customer assured of the sample quality and no additional wireline/BHS runs were needed

- Significant time and cost savings were achieved by providing the services at the well site, saving days of operations per well. Partial fluids analysis in a fixed onshore laboratory typically takes 5-10 days, but Expro was able to provide quality data in few hours after the samples were collected

- Expro delivered multiple successful projects that resulted in no lost time and no HSE events

- The samples and data collected provided critical information to baseline geochemical conditions in saline aquifers and complemented the creation of a robust Measurement Monitoring and Verification (MMV) plan for CO₂ injection and regulatory reporting to the EPA

Contact

For further information, please contact ExproSES@expro.com.

©2025 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU