Case Study

Mercury measurements in shut-in wells using downhole Non-Reactive Sampler

Contact

In Brief

NRS sampling allowed the client to obtain critical information on subsea development to resume production

Product Line

Customer Challenges

- Expro's client had a well that had been shut in for a number of years due to the formation water break through, which they wanted to return to production

- The well could not flow back to production without confirming contaminant levels were within acceptable limits

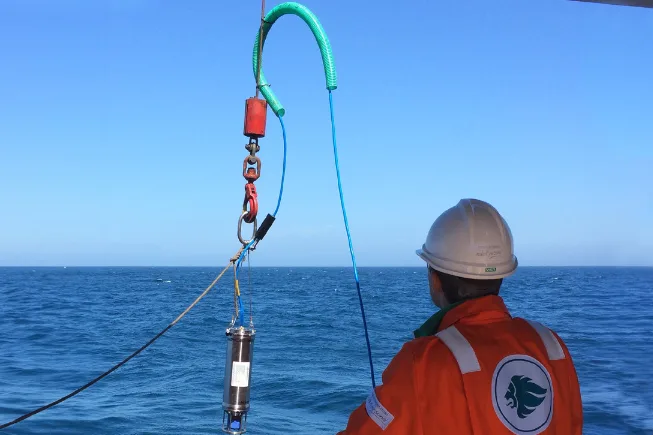

- As a subsea development, downhole sampling from a lightweight intervention vessel was the only option for the client

- Expro's Non-Reactive Sampler (NRS) provided a unique opportunity to obtain representative mercury data

- The client needed to confirm mercury concentrations from both water and hydrocarbon producing zones

Expro Excellence

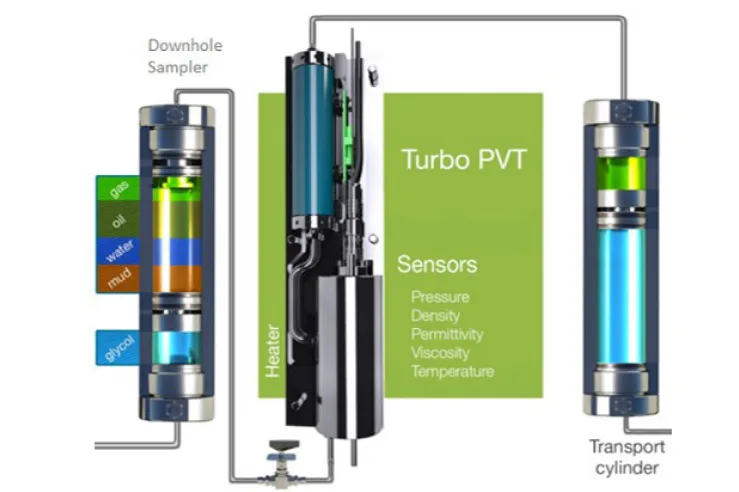

- Expro deployed a sampling string consisting of three NRS in conjunction with three Pressure Compensated Samplers (PCS)

- Tools were configured in a bundle with electronic clocks to trigger sampling at different depths, at predetermined times

- All samples were captured as planned and retrieved to the surface

- Mercury analysis was performed on the vessel immediately after the tools reached the surface to ensure the most representative measurement, using atomic absorption technique for high accuracy

- PCS were transferred to transport cylinders

Value to Client

- Within the constraints of the operation, Expro were able to obtain representative samples and give accurate mercury data on the well fluids

- Using Expro's novel NRS, the unique mercury capture mechanism ensured that all mercury remained in the sample until analyzed, with no losses due to scavenging

- Mercury concentrations were quantified in all samples

- The client was able to confirm that mercury concentrations were within specification and was, therefore, able to bring the well back into production

- Our sampling and analysis were delivered with zero NPT

Contact

For further information, please contact WFM@expro.com.

©2025 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU