Case Study

Compact large bore landing string allows operator to use rig of convenience to achieve first oil

Contact

In Brief

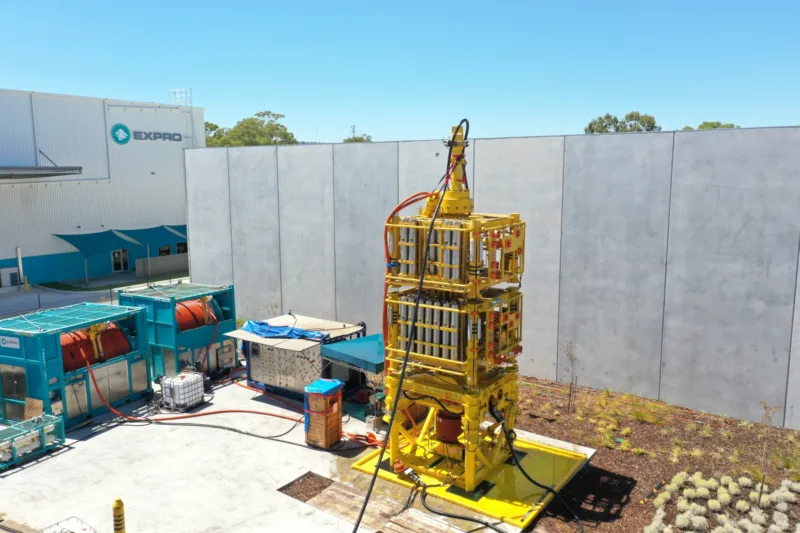

Expro's compact large bore landing string allows operator to use rig of convenience to achieve first oil

Product Line

Customer Challenges

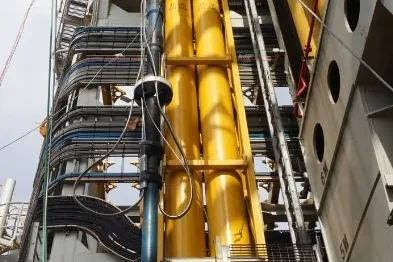

BP required a vertical tree system with a compact BOP stack on the PBLJ semi-sub for the new Arundel field in the North Sea - the allowable space was extremely limited utilising an existing rig, therefore standard equipment options would not fit

Expro Excellence

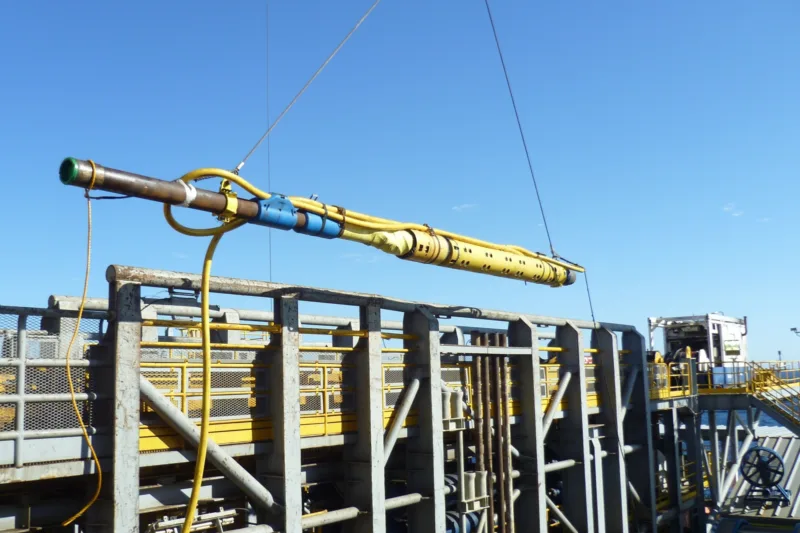

- A review of existing equipment variations was undertaken, however the challenge was the space available within the stack - Expro undertook to design and custom system inclusive of a full large bore landing string assembly with offset adaptor and helix sub-assemblies

- The bespoke system comprised a one piece slick joint, helix and offset adaptor with a 180o orientation window (versus 360o) and an upper section c/w latch from the Expro Landing String Assembly (ESLA) direct hydraulic (DH) system, which enabled it to fit the BOP stack

- Expro collaborated with BP to agree the solutions - sketch to engineering took 15 working days; thereafter manufacturing took 12 weeks

Value to Client

- Compact large bore landing string allows operator to use rig of convenience to achieve first oil

- BP were able to produce from the new field without the need to increase the BOP stack, which would have had cost and time implications

- The revised stack saved >20 inches and cost approximately 88% less than than the combined cost of a new global riser analysis (GRA), manufacturing, rig installation time and testing

Subsea test trees have become the established safety system for well commissioning and intervention, with new standards developed to ensure well integrity is maintained at all times.

Expro are renowned for bespoke unique solutions, meeting or exceeding or clients' needs. From concept to design, Expro are proud to meet the demands of today and are well structured for the demands of tomorrow with industry leading innovations.

Contact

For further information, please contact subsea.enquiries@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU