Case Study

Control line safety device reduces Red Zone risks, increases running speeds by 2.9 minutes/joint in series of smart completions in SE Asia

Contact

In Brief

Expro's SCLMA facilitated a reduction in manual handling associated with clamp installation, further supporting safety

Product Line

Region

Customer Challenges

- An operator running smart completions aboard a cantilever jack-up rig sought a solution to reduce hazards to personnel, including red zone exposure, dropped object risks, and working at heights. In addition, the operator looked to optimize completion running operations and save rig time through increased efficiencies

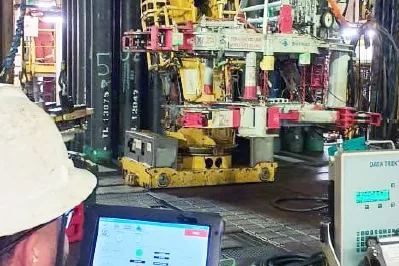

Expro Excellence

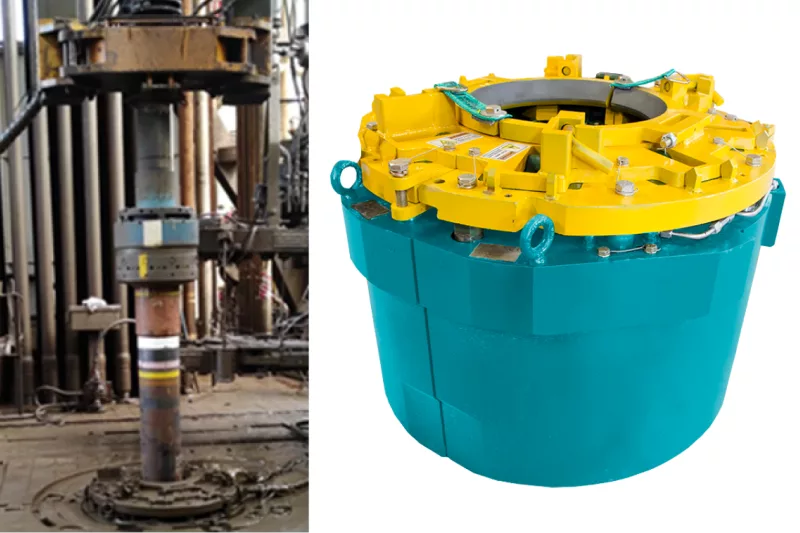

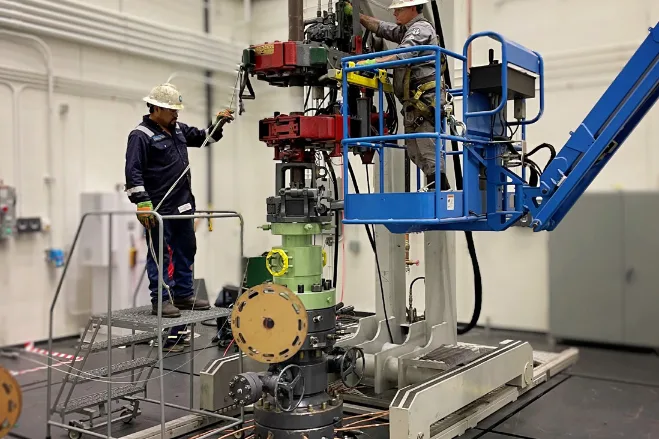

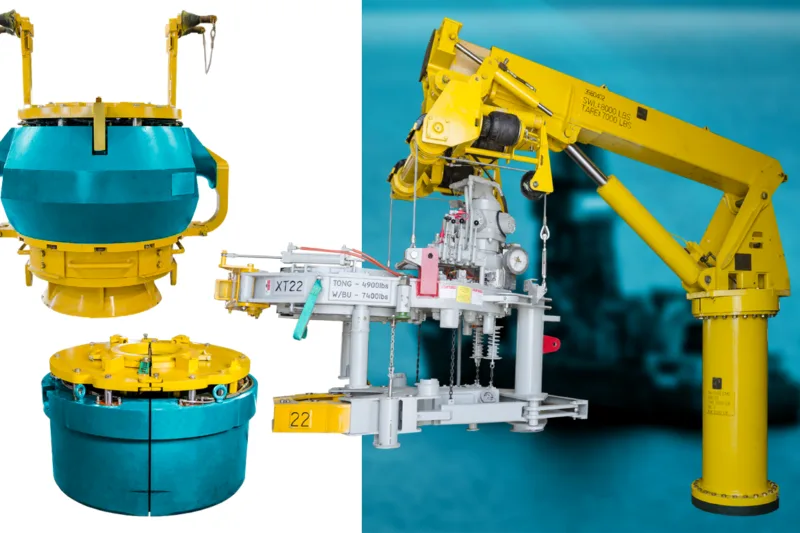

- The Expro Sheaveless COBRA® Control Line Manipulator Arm, also known as the Sheaveless Control Line Manipulator Arm (SCLMA), was selected for its ability to eliminate the use of sheaves in the derrick during smart completion running. In addition to eliminating sheaves and associated man-riding operations, it includes a failsafe " cut and secure" system in the event of uncontrolled descent of a string. It also offers multiple features that help improve control line integrity and reduces personnel on the rig floor

Value to Client

- Safety was enhanced through removal of the need to work at heights to hang sheaves, and through reduction of DROPS risks and personnel RED zone exposure. The SCLMA also facilitated a reduction in manual handling associated with clamp installation, further supporting safety

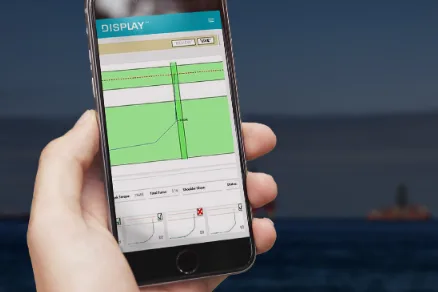

- When comparing performance data for smart well completions prior to and after the introduction of the SCLMA, the SCLMA resulted in marked percentage decreases in tubular running time. The SCLMA reduced the average slip to slip times to 5.9 minutes, from 8.8 minutes without the SCLMA. By eliminating tasks such as manriding for sheave installation and rig down, as well as multiple manual actions related to control line handling, the SCLMA resulted in an average of 7 hours and 23 minutes of time savings per job

- In response to the performance of the SCLMA, the customer deployed the tool on all local assets

- Eliminated manual handling

- Improved safety

- Increased efficiency

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU