Case Study

Cracking the code: DFOS provides insight into zonal injectivity and fracture growth in multi-zone water injection well

Contact

In Brief

DFOS intervention delivers zonal injectivity insight

Product Line

Region

Customer Challenges

- Our clients asset featured a selection of multi-zone water injection wells where there is some uncertainty around which zones were taking the injected fluids

- Additionally, the client sought to quantify fracture growth during injection to mitigate the risk of uncontrolled fracture extension, thereby assuring the long-term performance of the reservoir

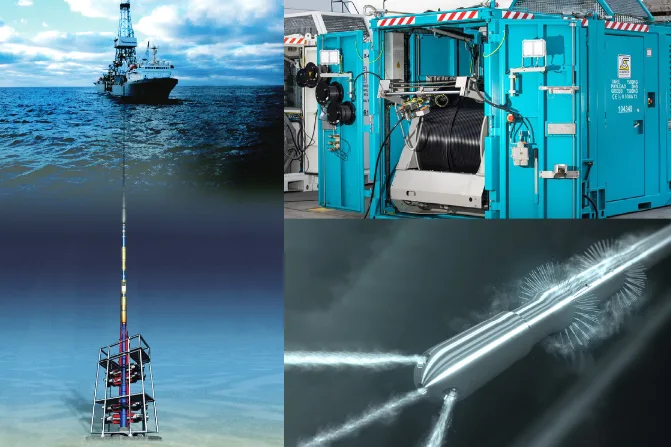

- To address these challenges, the client selected Expro's Distributed Fiber Optic Sensing (DFOS) Intervention solution to provide high-confidence insights to optimize injection strategies and safeguard reservoir integrity

Expro Excellence

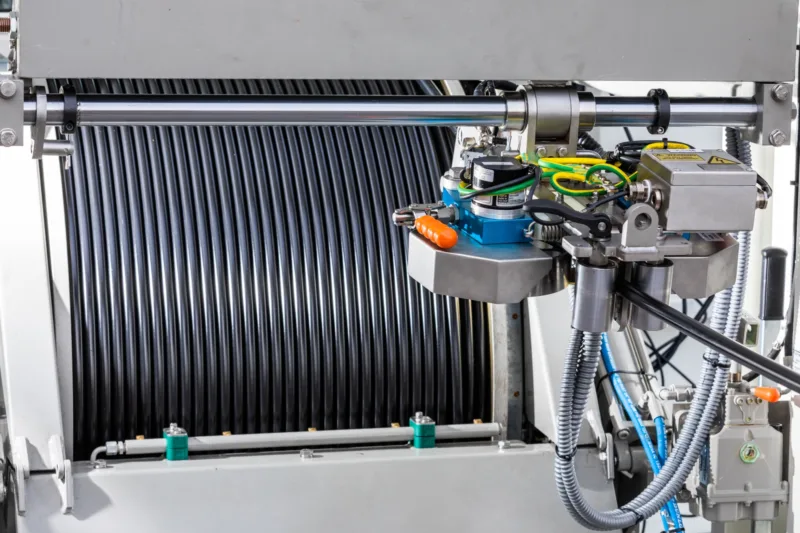

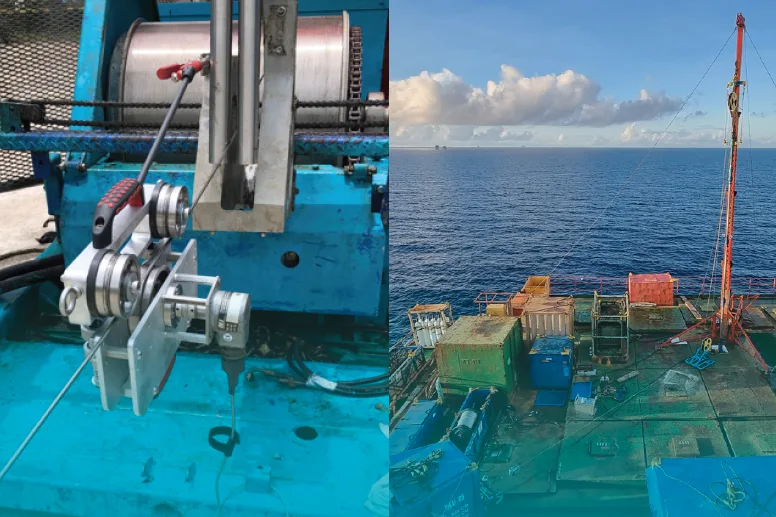

- Expro converted an existing Mechanical Slickline Intervention package into a DFOS Intervention Package, delivering a compact, cost-effective, and operationally efficient solution

- The surveillance program featured:

- A baseline survey

- A step rate injection test

- A warm back survey

- Expro’s DFOS eXtract® data processing software enabled rapid data analysis, with processed data transmitted to an off-site analyst for near real-time interpretation and analysis

- The data was integrated and visualized using Expro’s QikView™ software, providing a clear and actionable insight of dynamic well performance

Value to Client

- The complete well surveillance capability of the DFOS Intervention technology was used to gain actionable insight regarding the injectivity profile of the multi-zoned well

- The conversion of an existing Mechanical Slickline Intervention package into a DFOS Intervention Package enabled our client to gain real-time well insights while minimizing footprint and intervention costs

- High Injectivity was confirmed in two of three zones during the step rate test, with the third zone exhibiting a rate dependant zero to low injectivity characteristic

- Analysis of the DFOS data determined fracture growth during injection, with this insight being used to mitigate against the risk of uncontrolled fracture extension

Contact

For further information, please contact wellintervention@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU