Customer challenges

- As a signatory to the zero routine flaring commitment agreement by oil and gas producers, Nigeria is enforcing stricter regulations with more severe penalties on operating companies failing to meet zero flaring requirements

- To commercialise the associated gas being flared an accurate, portable metering system was required to determine the most economical method to modify facilities to process the gas

- Expro was asked to measure the gas flared on all flow stations where little or no metering was installed or available

Expro Excellence

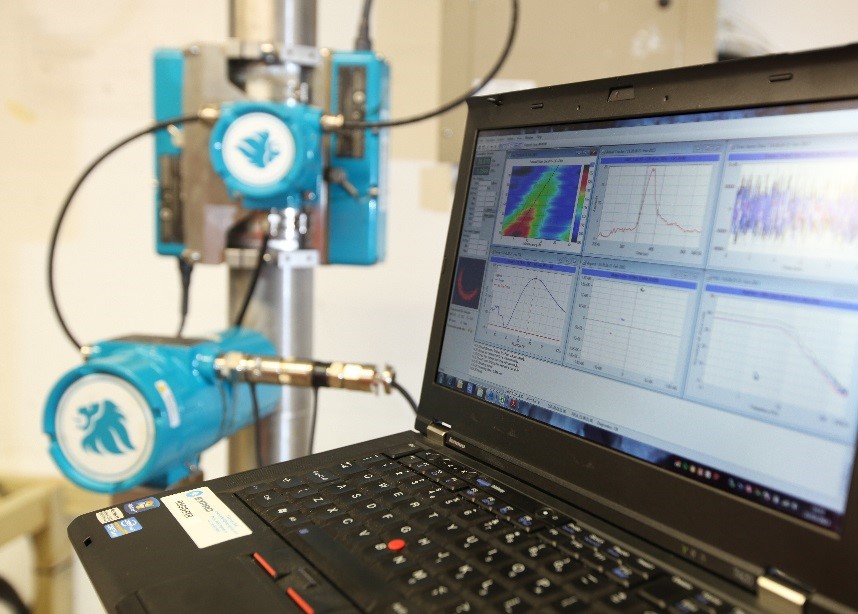

- Expro during the flare measurement project installed metering on all the flare lines on each flow station to ascertain the total amount of gas which was flared on each flow station on a daily basis

- Various meter sizes were installed on multiple measurement locations with minimal footprint and no disruption to production

- Flare measurements have been carried out on high pressure low pressure separators and flow lines. The pipe sizes ranged between 6" and 24"

Value to client

- Operating company was able to accurately report flare gas and reduce penalties

- The customer implemented process upgrades to further minimise the requirement to flare

- The operator also identified a potential variation in a new wells GOR that initiated remedial intervention