Customer challenges

- The customer’s well started up in February 2017 and they started to experience downhole chemical injection issues. The chemical injection system was out of operation for a few months

- In February 2018, the well was shut in due to a failed inflow test on the subsea safety valve (SSSV). After various attempts using conventional broaching techniques, in combination with chemical treatment using bespoke SSSV remedial tooling, it was found to be unsuccessful

- A plug was then set to act as a fluid retention device while acid was deployed into the SSSV bore and surrounding area

- Operations were planned to pull the plug using a stroker tool, and thereafter utilise CoilHose to clean the tubing from below DHSV to surface, but when the operations started, they found that partly dissolved scale debris had dropped down alongside the TDR onto the plug, preventing the retrieval of the plug. Multiple runs where performed with e-line technologies without success

Expro Excellence

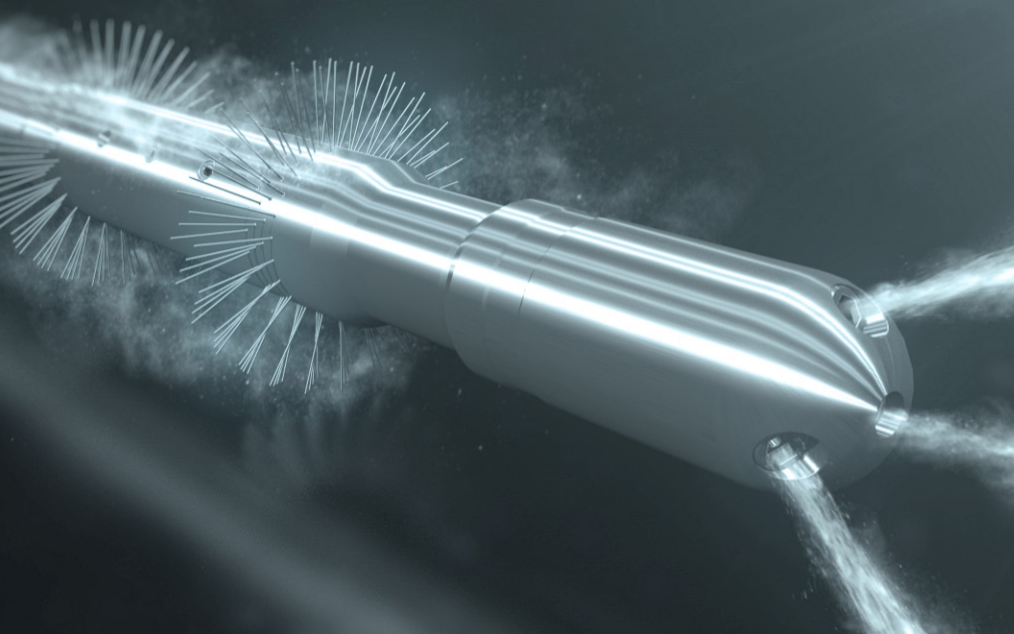

- Excellent cooperation between the client and Expro’s team, led up to the design and manufacturing of a 9 meter long spear with a turbo nozzle. Planning and execution was very effective and in short time the equipment was taken to location by helicopter. The spear was run alongside the 9.5 meter long TDR left on top of the plug, pumping 7,5% HCL to remove all debris above the plug. The plug was thereafter successfully retrieved

- Expro did 1 run (3 passes) cleaning the tubing with 7,5% HCL through our high pressure jet nozzles, clearing the upper completion of all scale and restoring the ID of the 7” tubing from approximately 5,5” to above drift diameter

Value to client

- Excellent cooperation and collaboration between Expro and the client’s intervention duty team during the project • Expro’s delivery of the CoilHose technology restored the production from this well avoiding a costly operation with Rig Assisted Snubbing

- Expro’s game changing technology was an alternative to existing solutions on the market saving time compared to utilising broaching operations

- The customer experienced less damage and better placement control compared to standard technologies