Case Study

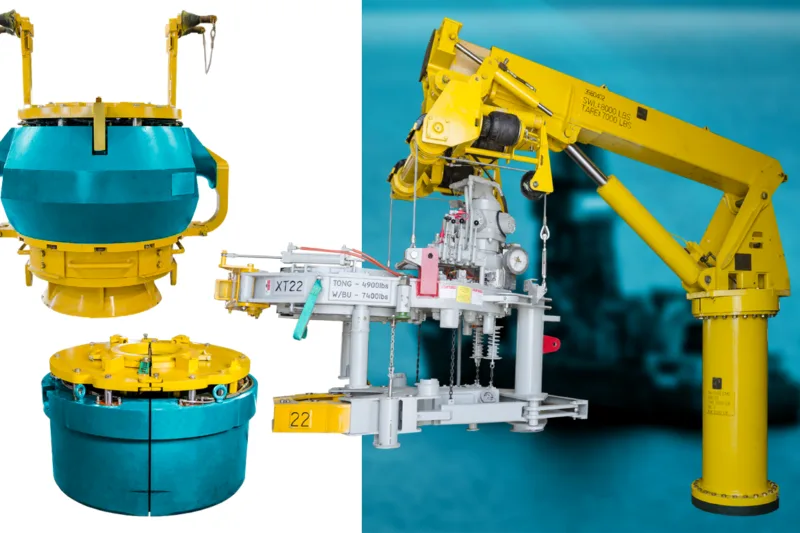

FX-600™ casing run performance deepwater, west of Shetland

Contact

In Brief

Casing string was successfully run to depth first time by simultaneously circulating and rotating through troublesome open hole zones

Product Line

Customer Challenges

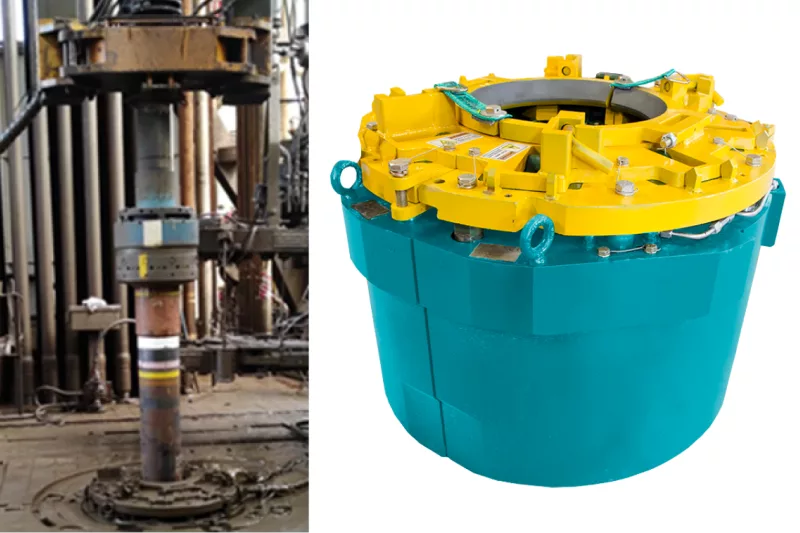

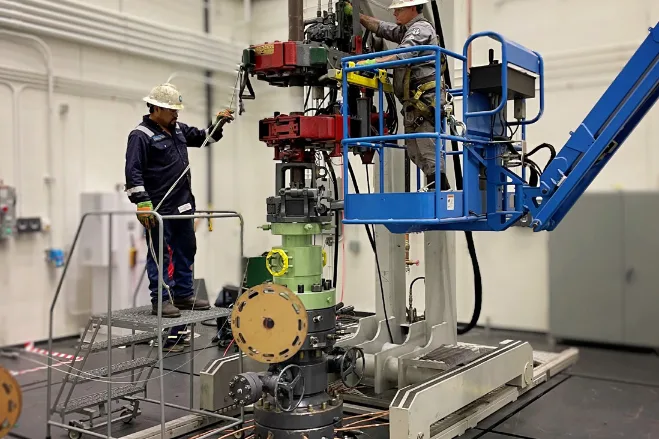

- To deploy and make up 9 5/8 in. x 10 3/4 in. casing string using Frank’s Tubular Running Services(TRS) FX-600™ CRT technology in a deep water well, west of Shetland, with zero health, safety, or environmental issues

- To reach the desired total depth (TD) in challenging open hole conditions, the client selected our FX-600™ for its ability to make up, fill up, rotate, circulate, and reciprocate the casing string

- simultaneously

- Zero equipment change out at 9 5/8 in. x 10 3/4 in. crossover due to the extended range capability of the FX-600™ tool provides safety enhancements and efficiency savings

Expro Excellence

- The extended range ability of the FX-600™ CRT in combination with the SBS ensured no static time in open hole whilst changing from the 9 5/8 in. to 10 3/4 in.

- Hole conditions were challenging so the tool enabled the client to simultaneously:

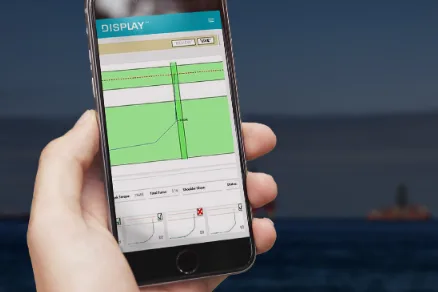

- Circulate at 1300 Ipm and 48 bar (700 psi)

- FX-600™ rotated the casing string at 40-70 rpm with torques monitored at 40 knm (30,000 ftlbs), 90% of connection maximum torque, to avoid damage to the connections and maintain well integrity

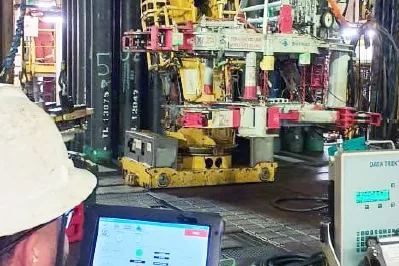

- FX-600™ CRT Driller Control module enhances safety by preventing the need for control panels and eliminating the operator being on the rig floor

- Rig-up time saved and risks reduced as no umbilical needed to be installed in the derrick

- BX elevator can remain rigged up to ensure a quick rig down whilst in open hole and transition to running drill pipe landing string

Value to Client

- The tool enabled controlled connection make-up, running and the monitoring of parameters to maintain well integrity, thus after cementing the string pressure tested successfully

- The FX-600™ was operated remotely by the driller with good communication in the doghouse and the Expro technician monitoring operating parameters

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU