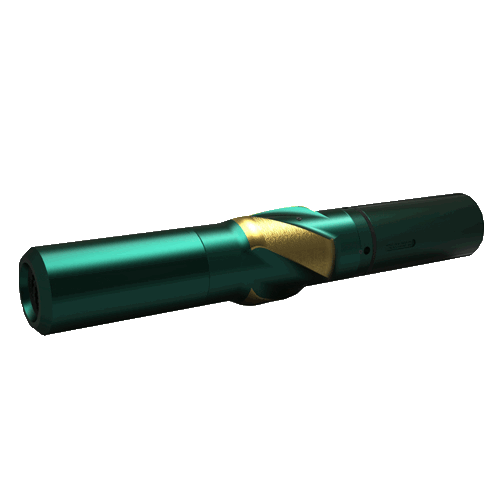

The HI TOOL® Harmonic Isolation Tool was deployed in an unconventional application while drilling vertically. Its role was to protect the bit from the severe axial and lateral vibrations experienced on the previous assembly. The goal was to drill the 12-inch section shoe-to-shoe in one run.

It was suspected that the main source of vibrations was a result of the PDC bit interacting with the formation. The HI TOOL® Harmonic Isolation Tool was run as a near-bit stabilizer within the rotary assembly.

In this well, with the HI TOOL® Harmonic Isolation Tool close to the bit, both axial and lateral vibrations were greatly reduced. This allowed the bit to sit flat on the well bore face, and for drilling to continue smoothly with normal parameters and a constant rate of penetration. The 5,500-foot section was drilled shoe-to-shoe in one run, achieving one of the lowest cost per foot ratios and the longest footage in the field, with a re-runnable bit graded 1-1.

• Reduction of axial and lateral vibrations

• Smooth drilling throughout section with no NPT