Case Study

Portable low carbon footprint solution for Wet Gas deliverability and production testing

Contact

In Brief

Expro's QPulse™ improved testing efficiency and accuracy for a MENA operator, reducing costs and emissions

Product Line

Region

Customer Challenges

- A major operator in MENA with multiple wells in tight gas fields aimed to improve testing efficiency for new and existing wells

- They had been using a conventional well-test setup with a separator, tanks and sand management, and the large setup had presented challenges

- Separator continuous measurements of liquid rates were not possible due to low flow rates, the flow was periodically directed to the tank to allow the measurements

- They have been exploring more efficient and accurate testing solutions to address the logistical and measurement challenges

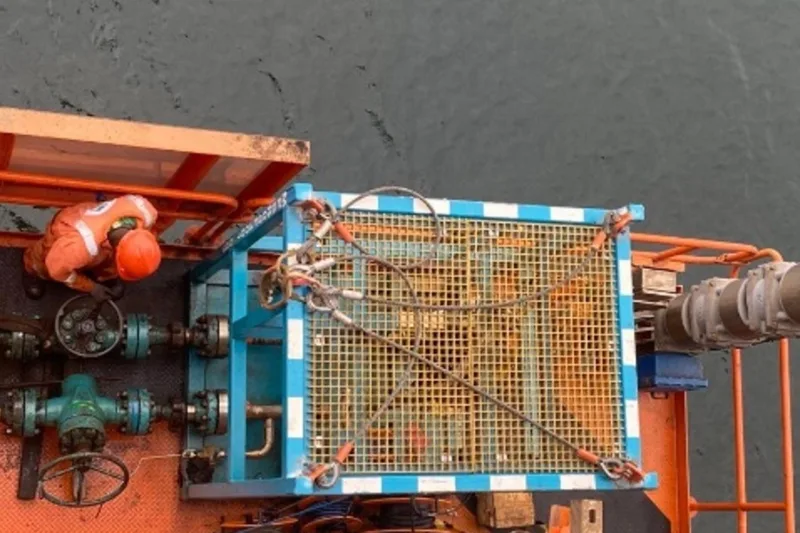

- Expro deployed QPulse™ alongside the existing well-test package for the first time to evaluate the technology

Expro Excellence

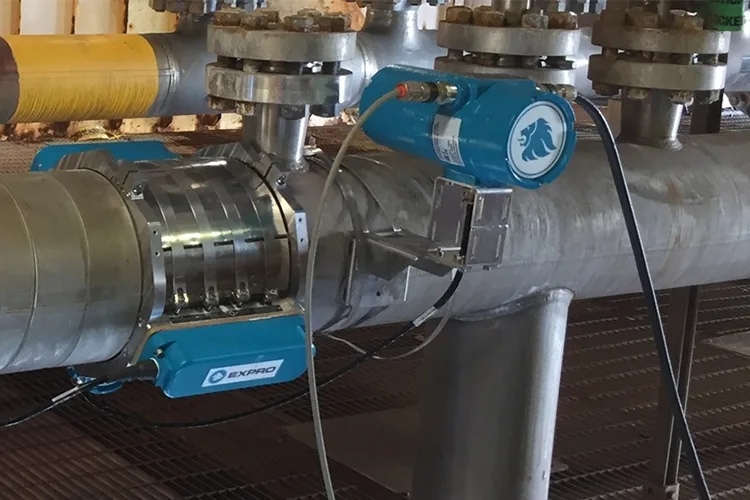

- Expro’s QPulse™ solution, a non-intrusive, portable multiphase flow surveillance solution that uses proprietary SONAR technology combined with MultiTrace® technology

- QPulse™ solution measures the gas, water and condensate flow rates without any piping modification, flow diversion or well shutdown

- Expro started measuring the gas and liquid flow rates from the initial period of well start-up through the test duration

- The system delivered reliable measurements from well start-up throughout the testing period, outperforming the traditional test separator method on the liquid rates by providing continuous data rather than periodic averages

QPulse™ is further deployed across two tight gas fields to test the technology on a large span of surface conditions and flow rates yielding excellent metering performance of gas, oil and water measurements

Value to Client

- Accurate testing solution which provided robust measurement unaffected by CO₂ or solids

- Early gas rates and liquid rates down to a few barrels/day independent of PVT inputs

- Small footprint solution implemented across the field facilitated a faster deployment, enabling a higher testing frequency

- Lower carbon footprint allows operators to receive the required data as well as meeting mutual environmental goals of reducing CO₂ emissions

Contact

For further information, please contact WFM@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU