Case Study

VERSAFLO™ Switch delivers efficiency and value during DST operations in Indonesia

Contact

In Brief

First VERSAFLO™ deployment in Indonesia DW is a wild success

Product Line

Region

Customer Challenges

- Expro was contacted by an Indonesian operator to assist with DST tubing RIH/POOH operations on a deepwater well.

- Expro’s TRS operations were ongoing on the rig, the client was looking for a solution to improve the efficiency of their drill stem testing operations

- They were looking for a solution which allowed the circulation on the fly when RIH or POOH on their 3,000m 4.5” tubing string, which would help prevent swabbing and speed up the tripping process without sacrificing surface operations

Expro Excellence

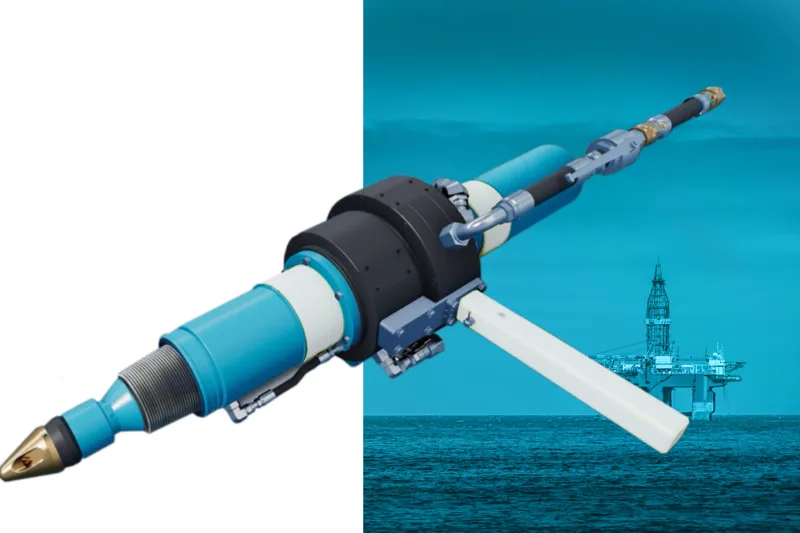

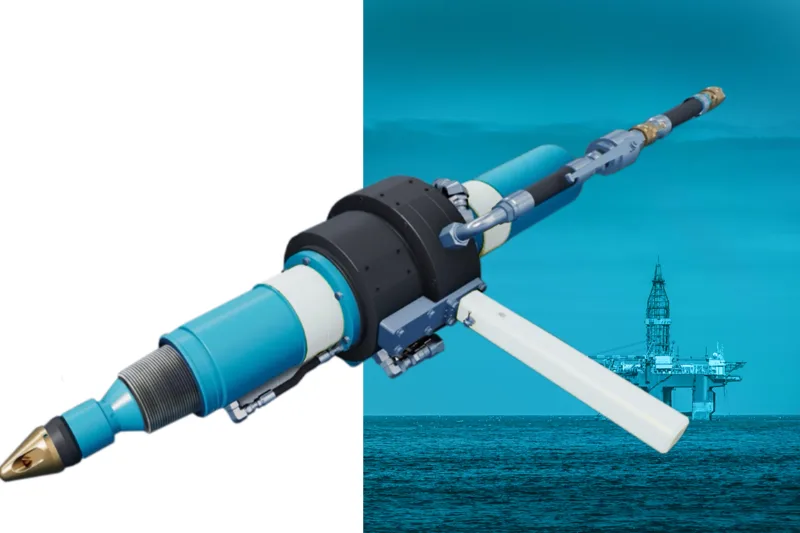

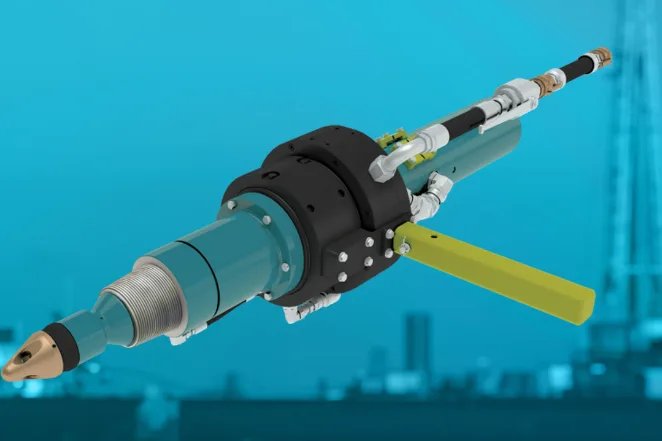

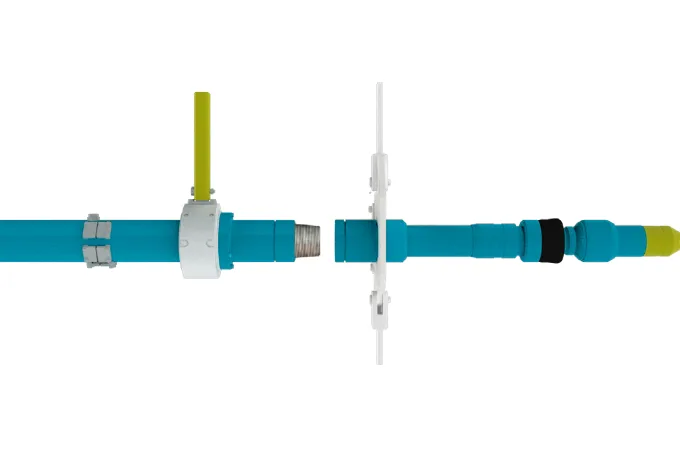

- Expro recommended its VERSAFLO™ Switch from the Time Saver series of tools to be utilized in Drill Pipe Mode and dressed it with bespoke packer cups for 4.5” Tubing with PH6 connections. The versatility of the VERSAFLO™ Switch tool, which includes a casing and drill pipe module, allowed the drill pipe module to be customized to run 4.5” tubing

- As the operator was looking for a solution in an abbreviated timeline, Expro was able to rely on it’s extensive expertise and engineering groups to deliver the custom application tool to the operations in in the Andaman Sea, Aceh in only 51 days, tools and accessories were procured from 3 different countries. Tools were then assembled in Indonesia and Expro delivered true value and efficiency to the Indonesian Operator during their critical 4.5” tubing operations

Value to Client

- Upon rig up, the VERSAFLO™ Switch managed to assist with freeing the tubing string from bottom and subsequently saved valuable hours by allowing circulation on the fly, as there was no other viable option to make the tubing up to the top drive for circulation. A specially designed ID sealing packer cup extends into the tubing string and seals up to 5000psi, allowing a quick and easy solution to tackling swabbing and pumping out of hole. Before rigging up the VERSAFLO™ Switch, the rig spent 6 hours pulling one stand conventionally due to pipe getting stuck, once the Switch tool was rigged up, the operator was able to circulate the string free and finish pulling all subsequent stands of tubing without issue

- By assuring the wellbore quality during the Drill Stem Testing operations, the operator was able to efficiently run and pull the testing string, and prove the long-term viability of the asset for future production and development purposes, saving cost and time and aiding in the long term profitability of the asset for the operator

Contact

For further information, please contact wellconstruction@expro.com.

©2026 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU