Case Study

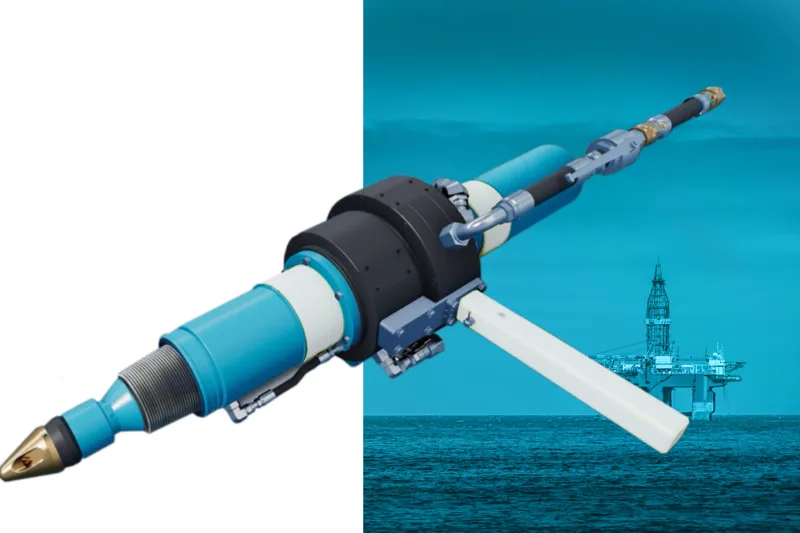

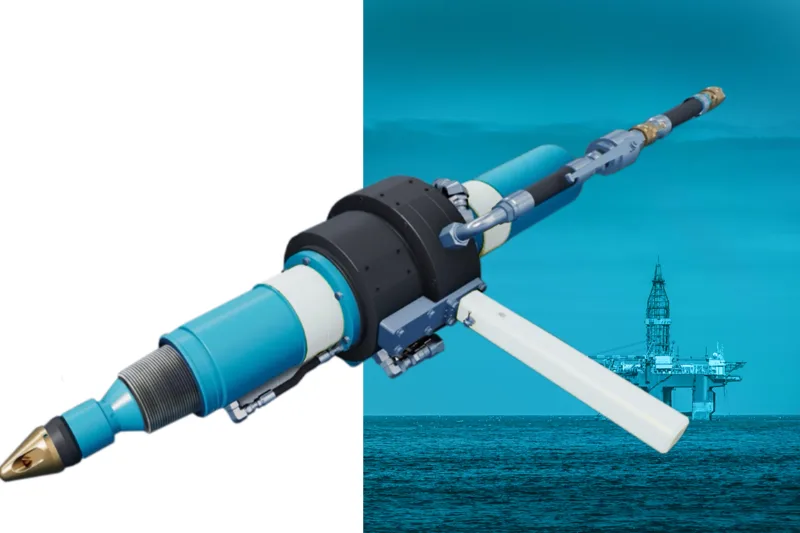

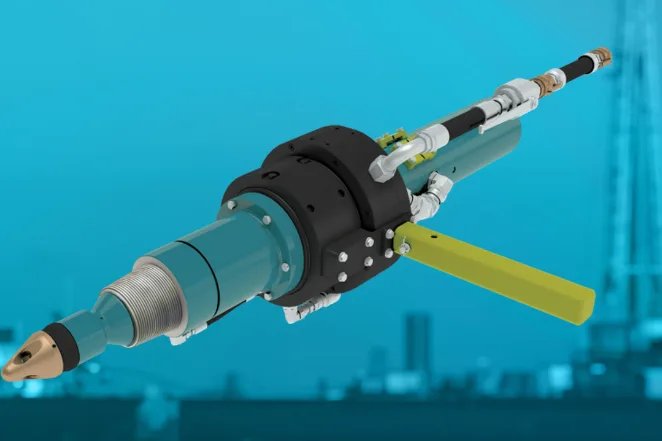

VERSAFLO™ Switch Tool has successful run in the Mediterranean

Contact

In Brief

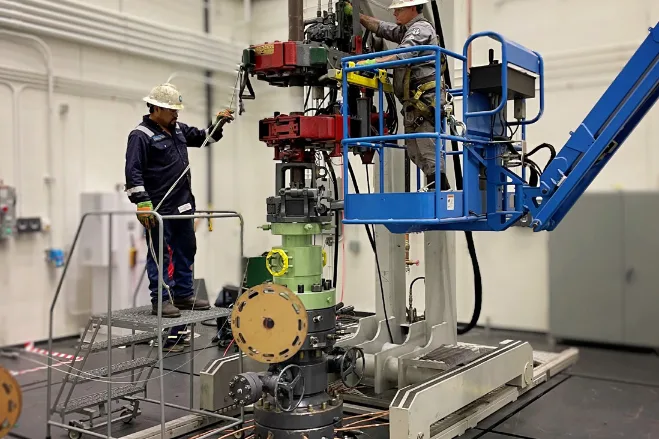

VERSAFLO™ Switch tool, coupled with its wireless control unit, provided a safe, fast, and efficient way to take flowback without the need to mechanically connect the top drive to the drill string

Product Line

Customer Challenges

- In response to an operator seeking a time-saving solution while running deep liners aboard a semi sub rig in the Mediterranean, Expro presented the VERSAFLO™ Switch Casing and Drill Pipe Flowback and Circulation Tool configured to VX57 connections. Goals for the operation included reducing the time circulating drilling fluid, taking flow back and reducing the risk of becoming differentially stuck

Expro Excellence

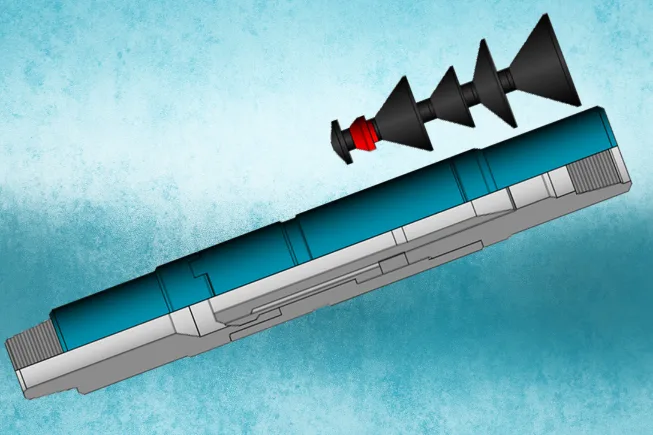

- In this case, the Drill Pipe Module of the VERSAFLO™ Switch tool, coupled with its wireless control unit, provided a safe, fast, and efficient way to take flowback without the need to mechanically connect the top drive to the drill string. The automated internal fluid valve protected against unwanted fluid circulation from the Kelly hose pressure head. Additional time savings resulted from a quick change in packer assemblies for the landing string from 5 7/8“ to 6 5/8

Value to Client

- Casing and landing string were successfully run without issues

- Not having to screw into the drill pipe to take flow back every connection while running the liner greatly reduced the time required for the operation. The versatility and ease of the quickly interchangeable packer cups saved time while running different sizes of drill pipe, and overall over the course of the job. The incremental time savings across the landing string and other parts of the operation added up approximately ten hours overall

- The customer was pleased with the performance of the VERSAFLO™ Switch tool

- No losses observed over the entire liner run

- Increased the running speed for landing string 2.5-4 mins/stand compared to conventional methods (9 mins/stand)

- Saved approximately one hour converting between casing and drill pipe modules compared to conventional methods

- Significant operating cost savings of approximately 10 total hours

- No mud spillage on rig floor

Contact

For further information, please contact wellconstruction@expro.com.

©2025 Expro. All rights reserved.

EXPRO HOLDINGS UK 2 LIMITED

Registered in England and Wales

Company number: 06491951

Registered office address: Second Floor Davidson House, Forbury Square, Reading, Berkshire, United Kingdom, RG1 3EU