- Home

- Products & services

- Well Construction

- Well Flow Management

- Subsea Well Access

- Subsea Test Tree Assemblies

- Intervention Riser System

- Riserless Well Intervention System

- PRT Offshore

- Motion Compensated Coiled Tubing Lift Frame

- Inline Compensator 600T

- Inline Compensator 220T

- ProFrame™ Coiled Tubing Lift Frame

- HOSS™ Wireline Lift Frame

- Gate Valve Flowhead

- Surface Test Tree

- Quick Union

- Lubricator Valve

- Subsea Landing String

- Subsea Controls

- ProComp™ Tower

- Intervention Work Tower

- Blue Sky Tower

- Accessories & Rental Tools

- Contact Us

- Well Intervention and Integrity

- Coretrax

- Sustainable Energy Solutions

- Case studies

- Media hub

- Careers

- Citizen of the world

- Contact

- Our 2023 Sustainability Review

- About Us

- Investors

- Locations

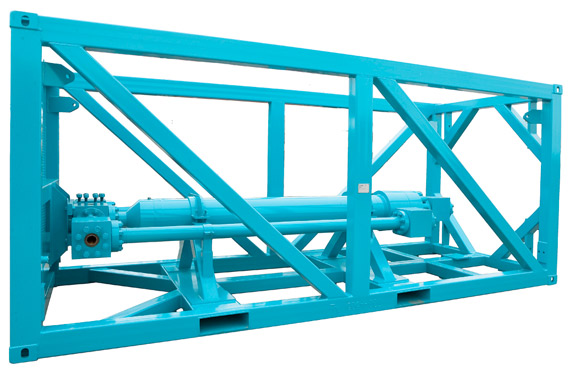

Desander

The wellhead desander is an innovative product from Expro which enables the recovery of sand product from well streams during well testing, hydraulic fracturing well clean-up and coil tubing or snubbing work over operations. It can be utilised upstream of the choke manifold to reduce abrasive matter therefore optimising the operability and prolonging the life of thewell testing equipment. It is well suited for HPHT conditions because of their rugged design and flexible components materials.

The well fluids from a predominately gas flow with GOR > 10,000 cf/bb are routed from wellhead to the desander. The well effluent enters the desander vessel tangentially and the resulting centrifugal force exerted on the spinning fluid pushes the denser phase (sand) to the wall of the vessel. The clean well fluids at the core are forced up by pressure and out of the outlet pipework. The sand drops into the bottom of desander vessel due to gravity. The settled sand/solids can be periodically dumped to the clearing / disposal outlet pipework via the severe service choke without shutting in the well at any period of the clean-up program.

The modular, skid mounted desander comes complete with a process bypass line and a strong lifting and frame. The unit comprises pressurised cylinder vessel, manual or optional hydraulic isolating gate valves and a hydraulic choke along with instrumentation manifold which enables pressure monitoring, equalisation and bleed off of the desander. The hydraulic choke valve is operated by the control console provided with the system.

Find detailed information about our products and services.